-

Designed to recycle:

-

Blow molded parts as bottles, containers

-

Injection molding parts

-

Food packaging containers, ....

-

-

Sorting & prewashing, wet grinding, hot washing, separation, centrifugation, pelletizing

PE/PP FILM MATERIAL RECYCLING LINE

-

Designed to recycle:

-

Food packaging film, woven bags

-

Wrapping films, ....

-

-

Washing (cold and hot)

-

Shredding, crushing, cold washing, hot washing separation, squeeze drying, agglomerating, pelletizing

BOTTLE TO BOTTLE RECYCLING LINE

-

Food grade quality PET

-

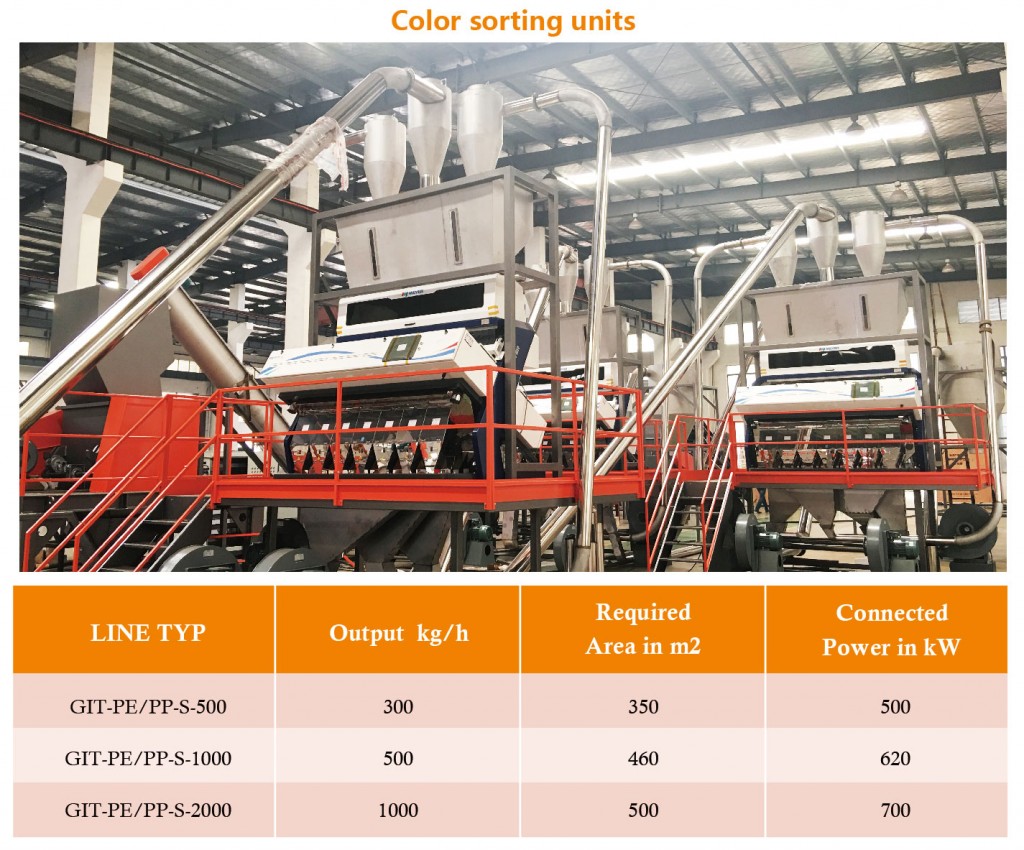

Optical sorting systems for bottles

-

Label separation

-

Glue removal with chemicals (caustic soda), friction and heat power

-

Optical sorting systems for flakes

-

Modular system to reach different needs from our customers

-

Optional: Water treatment system available

OUR ADVANTAGES AND WHY TO CHOOSE US:

-

Austrian know how (30 years of experience), manufactured in China

-

Austrian quality control in China

-

Austrian contract partners

-

Top price - performance ratio

-

In-house engineering

-

In-house R&D for new machine development

-

Careful washing

-

Careful sorting

-

Complete lines, or stand-alone units

-

Bale opener, pre-washer, bottle label remover, crusher, shredder, hot washer, inclined floating washer, horizontal centrifugal dryer, squeeze dryer, friction washer, conveyor belts, .......

-

Hot washers for glue removal with chemicals (caustic soda), friction and hot water treatment system available

-

Simple line concept or high-end set ups available

-

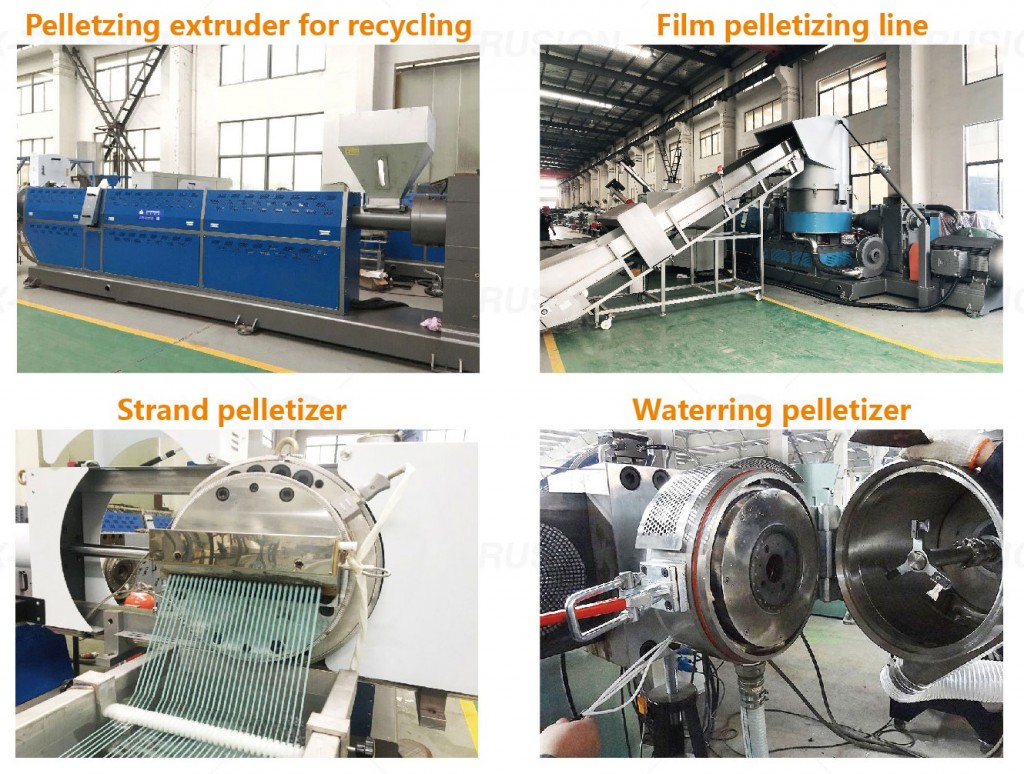

In combination with pelletizer lines for PET, PP/PE, LDPE, ...

-

Co-Rotating extrusion (depends on application)

-

Counter rotating extrusion (depends on application)

-

2-stage extrusion (depends on application)